3M™ Dyneon™ Fluoroplastic PVDF 6108/0001

聚偏二氟乙烯 (PVDF)

3M Advanced Materials Division

Polyvinylidene Fluoride (PVDF) is ideal for multiple applications across a wide array of industries. Widely used in the chemical process industry, wire and cable industry, semiconductor industry, and oil and gas industry, PVDF is also gaining recognition in automotive, building, electronics, food processing, pharmaceutical and batteries.

3M™ Dyneon™ PVDF 6108/0001 is easily processed under a variety of conventional thermoplastic conversion techniques, being particularly suitable for injection molding. This grade is designed for parts that require shrinkage rates of 2-3%. PVDF 6108/0001 is inherently pure and chemically resistant against a variety of aggressive fluids and solvents. PVDF 6108/0001 exhibits excellent dimensional stability, abrasion resistance and high strength, and maintains its mechanical properties at elevated temperature.

Features and Benefits

•High temperature capability

•Excellent chemical resistance to a variety of aggressive fluids and solvents

•Good permeation resistance

•Smooth, anti-fouling surfaces

•Injection molding grade

•Low shrinkage rates

•Excellent strength and dimensional stability

•Good color stability

材料特性:纯度高、高强度、抗溶剂、良好的加工性能、良好的颜色稳定性、耐化学品良好、耐磨损良好、高耐热、收缩性低、High Dimensional Stability

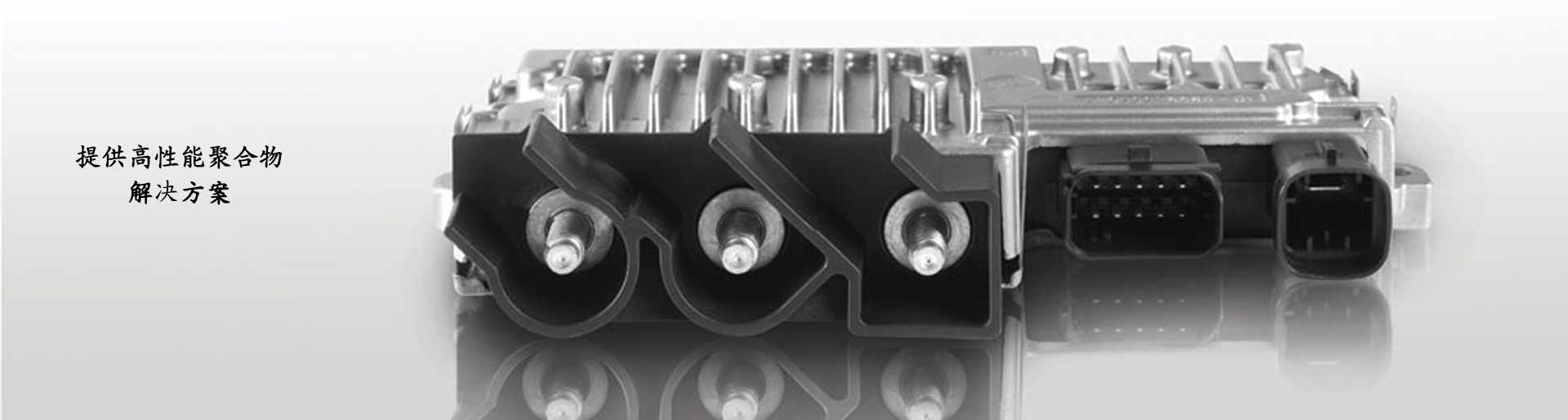

材料用途:电池、电气/电子应用领域、电线电缆应用、建筑材料、汽车领域的应用、石油/天然气用品

加工方法:注射成型

供货地区:北美洲、欧洲

| 物理性能 | 额定值 | 单位制 | 测试方法 |

| 密度 | 1.78 | g/cm³ | ISO 1183 |

| 熔流率(熔体流动速率) | ASTM D1238 | ||

| 230℃/2.16 kg | 8.0 | g/10 min | |

| 230℃/5.0 kg | 24 | g/10 min | |

| 收缩率 - 流动 | 2.0 | % | |

| 吸水率(24 hr,23℃) | < 0.040 | % | ISO 62 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

| 抗张强度1 | ASTM D638 | ||

| 屈服,23℃ | 50.0 | MPa | |

| 断裂,23℃ | 40.0 | MPa | |

| 伸长率1 | ASTM D638 | ||

| 屈服,23℃ | 8.0 | % | |

| 断裂,23℃ | 35 | % | |

| 弯曲模量2(23℃) | 1930 | MPa | ASTM D790 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

| 载荷下热变形温度(1.8 MPa,已退火,4.00 mm) | 112 | ℃ | ASTM D648 |

| 熔融峰值温度 | 169 | ℃ | ASTM D3418 |

| 可燃性 | 额定值 | 单位制 | 测试方法 |

| 极限氧指数(3.00 mm) | 44 | % | ASTM D2863 |

| 备注 150 mm/min 22.0 mm/min |

|||